Silicone Adhesion & Bonding

Silicone Adhesion is no more a challenge!

Silicone adhesion problem to other surfaces makes it incompatible in various scenarios in spite of having all the other promising properties required. This Silicone based Compo-SiL® technology is a great innovation in the polymer industry as well as for its use in the various industries like health care, electronics, automotive, aerospace, industrial assembly, building, textile etc. Find out more silicone background in please check our FAQ

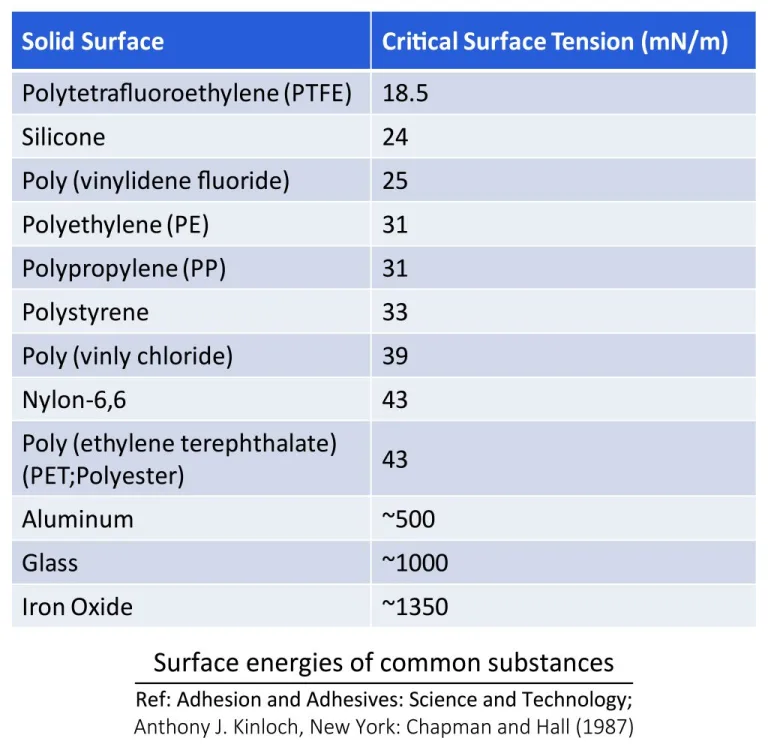

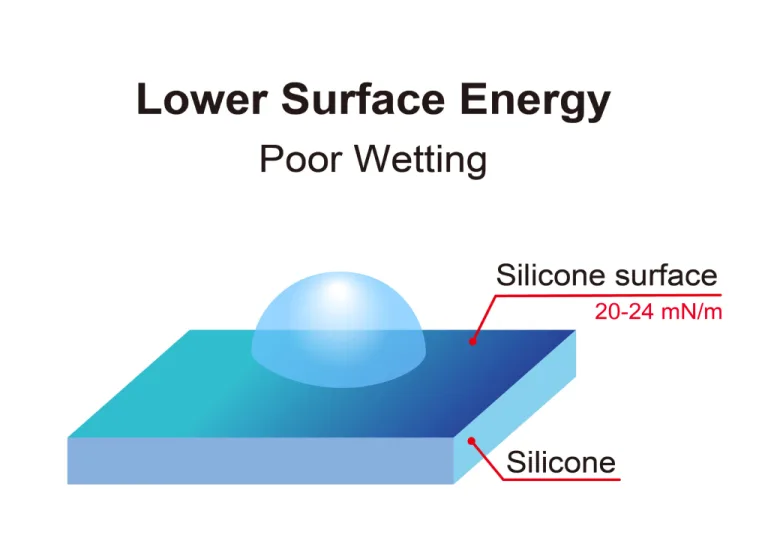

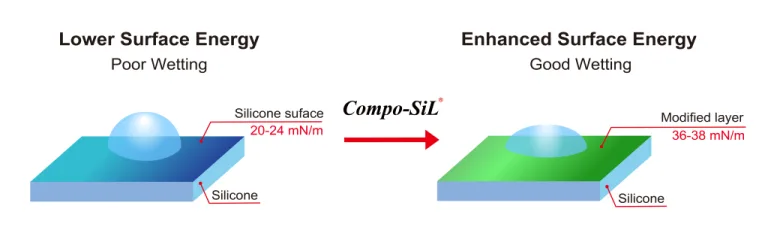

This problem of silicone bonding or low silicone adhesion strength has been thoroughly studied since many years and possible solutions were also proposed that comes with their own limitations. Materials with low surface energy tends to have weaker adhesion strength towards other materials as they lack molecular attraction forces. Silicone being one of the low surface energy materials shows pure wetting on its surface. If some water is poured on a silicone sheet: It will just run off or it won’t wet out on the surface which is not a required property.

Dyne test inks are a simple and inexpensive way to estimate surface energy and require no special training. Surface energy is usually given in units of dynes/cm or mN/m. Silicone has surface energy of 24 dynes/cm. This value is not high enough so that silicone adhesion to other surfaces can be strong.

Compo-SiL®: A solution for Silicone Bonding

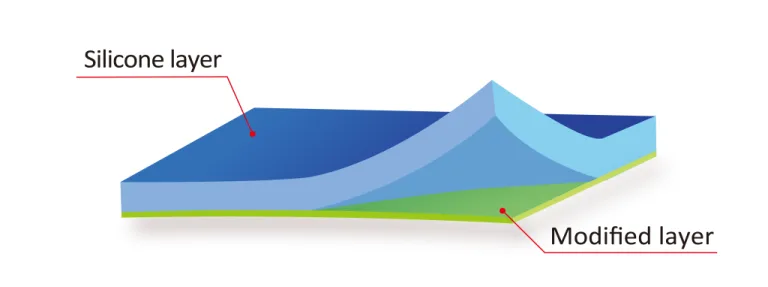

Compo-SiL® technology has been successful in enhancing the silicone adhesion problems by having an ultra-thin modified layer above silicone that enhances the surface energy to 38 dynes/cm. Although there are other solutions available for silicone adhesion like plasma techniques and other silicone adhesives, however these are highly expensive and complex solutions which requires great precision, man power and may present environmental or safety issues.

The bonding strength between the silicone and modified layer in Compo-SiL® Technology has been tested rigorously using standard methods as well as GS developed methods. All the tests have shown cohesive failure within the adhesive layer or cohesive failure in the adherend, demonstrating the strong bonding strength of the Compo-SiL® technology of General Silicones.

General Silicones offers diverse series Compo-SiL® based silicone Roll-to-Roll sheets with unique properties for various applications. With high expertise in silicone formulation, several processing methods and state of art of R&D, GS can customize silicone properties according to the demand of customers meeting their needs all over the world.