Certified Antibacterial Silicone Now Available From General Silicones

Antibacterial Silicone Sheets for Medical Grade Coatings

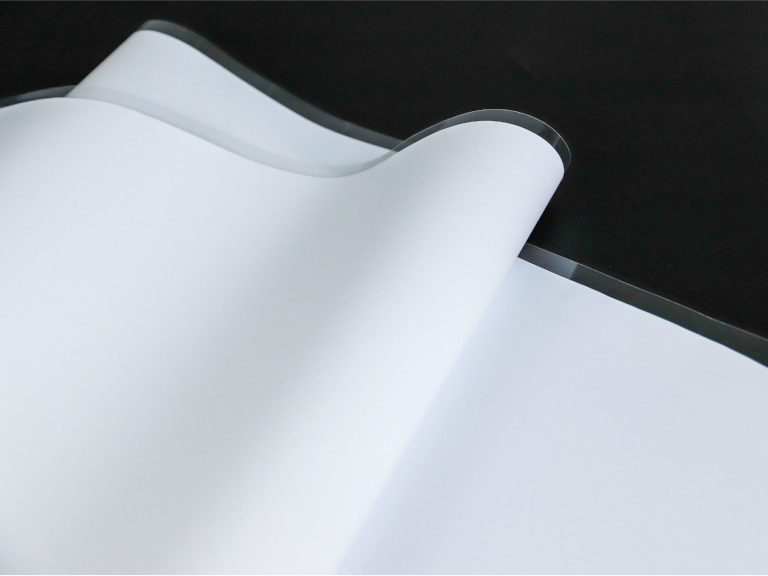

Hsinchu, Taiwan, March 5, 2021 – Experienced silicone product manufacturer General Silicones (GS) shares that its silicone rubber sheet products, including Compo-SiL® silicone rubber sheets, are now available in medical grade quality with certified antibacterial properties. The sheets are shipped in rolls that can be stored, cut, and applied using roll-to-roll processes or individually using standard adhesives in existing product lines for mass production.

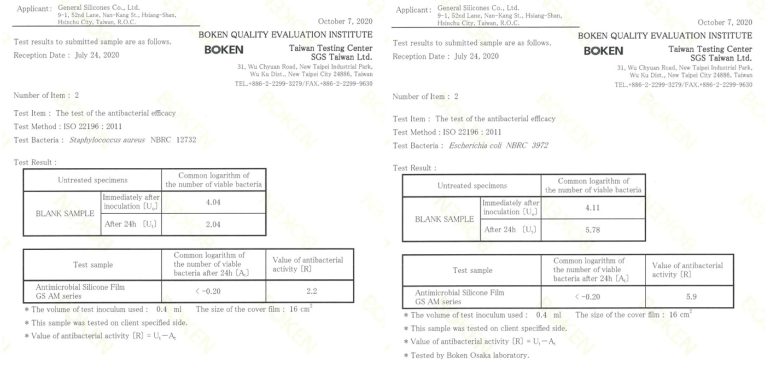

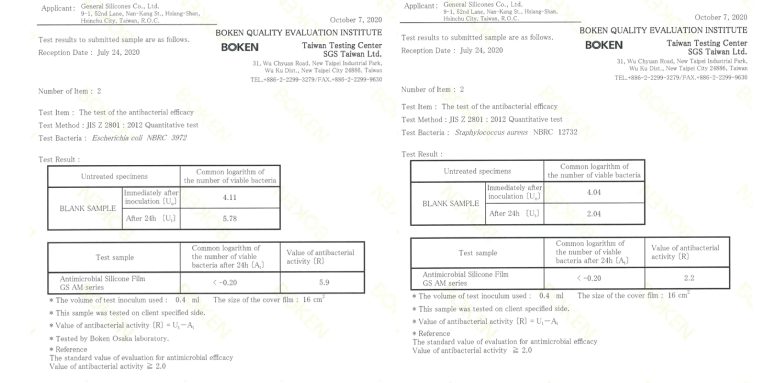

ISO 22196 and JIS Z 2801 Certified Medical Grade Silicone Rubber

With over 50 years of experience in manufacturing silicone rubber products, GS adjusts its silicone rubber properties to the clients’ requirements. GS supplies various medical product brands with medical-grade silicone and had its production re-certified for the latest antibacterial testing standards bacterial, the ISO 22196:2011 and the JIS Z 2801: 2012 With antibacterial properties, silicones are easy to sterilize and highly resistant to oxygen, ozone, UV light, aging, weather, and extreme temperatures. Most pathogens are also of hydrophilic nature that doesn’t allow them to stick to silicone surfaces due to their hydrophobic properties.

Test Method:ISO 22196:2011

Test Method:JIS Z 2801: 2012

Antibacterial Product Coating With Silicone Rubber Sheets

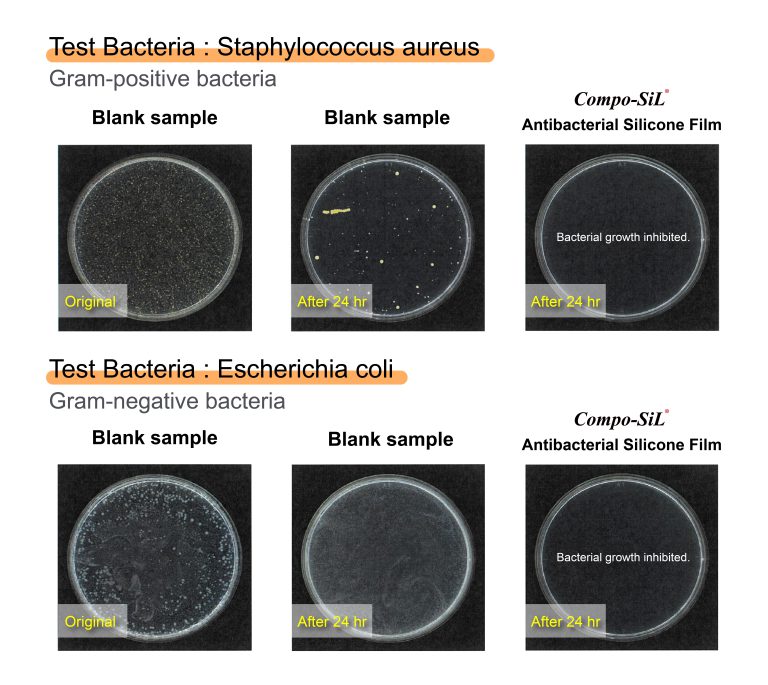

The antibacterial certifications demonstrate that silicone rubber used is effective against germs. The silver nanoparticles incorporated in the silicone material act as antibacterial agents to prevent dangerous microbes such as E. coli and MRSA from growing and multiplying on the silicone. As ionic silver affects the cell walls of gram-positive and gram-negative bacteria and fungi, it blocks the reproduction of the germs and prevents colonization of the protected surface. The antibacterial and hydrophobic properties of silicone offer an effective strategy to reduce the risks of cross-contamination.

Easy Adhesion With Common Adhesives Thanks to Compo-SiL®

All antibacterial silicone rubber sheets are made using the Compo-SiL® technology. All sheets ship to the client with a modified PU layer. The sheets can be easily cut and applied to surfaces using standard adhesives like PUR and to textiles using HMA adhesives.

Fighting Hospital Acquired Infections With Compo-SiL®

Various surveys estimate that millions of preventable deaths occur worldwide by hospital-acquired infections due to bacteria like E. coli and MRSA. Millions of patients worldwide get affected due to hospital-acquired infections, increasing mortality unnecessarily. A WHO (World Health Organization) report claims that of every 100 hospitalized patients, at any given time, 7 to 10 will get a hospital-acquired infection.

Hospitals and the medical industry strive to find solutions for an antibacterial surface that is medically accepted, highly durable, sustainable. The easy-to-apply Compo-SiL® silicone rubber offers a cost-effective and straightforward solution to fight bacteria at critical locations.

Suitable for Wide Range of Applications and Industries

Surfaces with antibacterial properties are advantageous in many situations, including factories producing food and products that need to match high hygienic standards and locations with many people visiting or passing every day. Silicone surfaces are easy to sterilize and do not react with disinfectants and detergents, effectively protecting the base material from aging and corrosion. The low surface energy of silicone prevents dirt and microbes from sticking to surfaces, making them easy to clean and sterilize.

Examples applications include:

- Medical devices and products

- Equipment in hospitals, bed handles, etc. for automobiles and transportation.

- Buttons, handles etc. in real estate industry.

- Lift buttons, car handles, staircase handles

- Antibacterial furniture, desks for hotels, schools, showrooms

- Lift buttons, staircase handles of public facilities

- Antibacterial surfaces in pharmaceutical and food manufacturing

Easily Printable Silicone Rubber With Compo-SiL® Technology

A specific advantage of the Compo-SiL® technology is that the modified PU layer can be printed using standard digital printing. This patented technology allows clients to create prints in never-seen detail, use colors and shades previously impossible with silicone rubber products. As the printed surface is inward-facing, it is protected by the silicone layer from degradation from disinfectants or UV lights used for sterilization.

Sourcing managers and manufacturers can contact the sales team of General Silicones at [email protected]

About General Silicones

General Silicones (GS) was founded in 1970 in Taipei, Taiwan, and is now represented worldwide – including Europe, China, Japan, and South-East Asian countries. GS is a major distributor of silicone materials and an active silicone products manufacturer with ISO 9001, IATF 16949, and ISO 14001 certifications. The company has manufacturing plants in Hsinchu, Taiwan; Wujiang, China; and Bac Giang, Vietnam. With decades of experience in this field, GS has the ability and capacity to provide a wide range of silicone products for many industries, including medical, automobile, consumer products, electronics, and IT. GS listed on Taiwan’s Emerging Stock Market in 2011 (TPEx: 4730). For more information about GS, please visit www.generalsilicones.com