In-Mold Decoration Film Innovation with Compo-SiL®

Silicone-based In-mold and Out-mold Decoration Films Are Pushing the Envelope

Hsinchu, Taiwan, October 27, 2022 – General Silicones (GS), an expert manufacturer of silicone products with 50 years of experience, is announcing the availability of its new product line of decorative film laminates based on its Compo-SiL® technology. Compo-SiL® silicone solves the problem of the adhesion of cured silicone rubber films to surfaces. The patented technology creates firm and durable adhesion to most surfaces during in-mold decoration (IMD) and out-mold decoration (OMD) processes.

Advantages of Silicone-Based Decorative Films for IMD/OMD

The unique properties of silicone rubber, in combination with the Compo-SiL® technology, allow IMD/OMD providers to supply their customers with a new range of surface properties and more flexibility in decoration.

GS manufactures Compo-SiL® decorative film with visual, tactile, and material properties that traditional decorative film cannot achieve.

Examples of silicone rubber film properties:

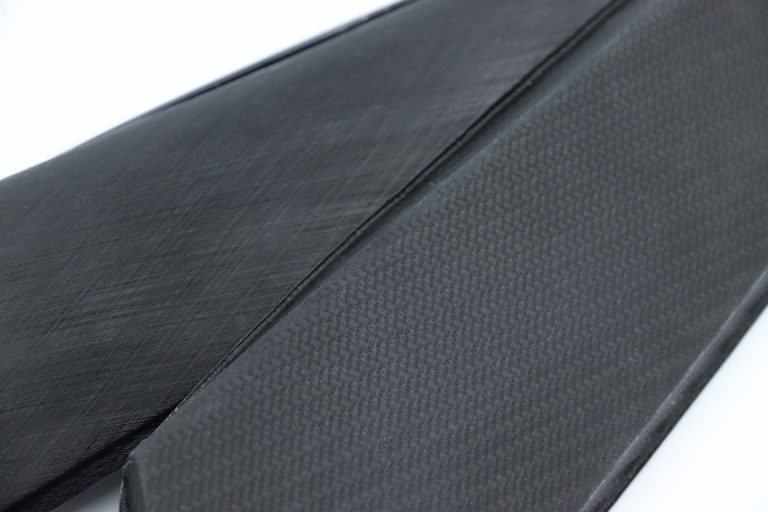

- Various leather types look and feel

- Custom surface textures (Wood, Metallic, Matte, etc.)

- Custom colors

- Digitally printed texts and designs

- Antiviral and antibacterial surfaces

- Fire retardant properties

- Anti-Slip surfaces

- Haptic touch HMI interfaces

Unlike thermal-plastic film, the thermal-set silicone rubber of Compo-SiL® film offers the added benefit that surface trim won’t disappear during thermoforming.

Silicone Rubber Film Withstands Harsh Environments

Plastic material quickly deteriorates from UV, water, and heat exposure in outdoor conditions. The high resistance to water, heat, cold, and UV light of silicone rubber gives brands creating products used in harsh outdoor environments to have decorations and logos that do not risk deterioration from environmental factors.

On-Site Digital Decorative Printing

Compo-SiL® decorative film can be shipped in rolls as a transparent film. The client digitally prints his customers desired designs on-site using standard digital printers. Testing different design concepts and creative ideas are now additional services mold companies can offer to their customer thanks to the flexibility of on-site printing.

Light Transmissive Decoration for HMI Interfaces in Vehicles

IMD/OMD in the automotive and transportation industry benefits from the ability of the silicone rubber film to transmit light and act as a touch interface. Interior roofs of aircraft, cars, and buses can provide specific patterns of light transmission; dashboards can include HMI touch interfaces to replace buttons.

Compatibility with Existing Machinery and Processes

Compo-SiL® film produced for decoration is compatible with existing IMD/OMD machinery and production processes. Clients do not need to invest additional resources to take advantage of the new properties that silicone rubber mold films provide.

A Green Material Suitable for Any Industry

Not only does Compo-SiL® provide the flexibility to use colors, textures, and patterns, but Compo-SiL®-based vegan leather film is a replacement for less environmentally friendly PVC and TPU for products requiring IMD/OMD.

The manufacturing of silicone rubber does not use harmful solvents and does not produce toxic chemicals when degraded or burned. The ability to adjust and enhance silicone rubber to different properties gives manufacturers of automotive interiors, consumer electronics, home appliances, sports equipment, and the medical product industry a new material to add value to their products.

Sourcing managers and manufacturers interested in Compo-SiL® for IMD/OMD can reach the General Silicones sales team at [email protected]

About General Silicones

General Silicones (GS) was founded in 1970 in Taipei, Taiwan, and is now represented worldwide – including Europe, China, Japan, and South-East Asian countries. GS is a major distributor of silicone materials and an active silicone products manufacturer with ISO 9001, IATF 16949, and ISO 14001 certifications. The company has manufacturing plants in Hsinchu, Taiwan; Wujiang, China; and Bac Giang, Vietnam. With decades of experience in this field, GS has the ability and capacity to provide a wide range of silicone products for many industries, including medical, automobile, consumer products, electronics, and IT. For more information about GS, please visit www.generalsilicones.com. For more information on Compo-SiL®, please visit www.compo-sil.com