IMD/OMD Applied Material

In-Mold Decoration (IMD) and Out-Mold Decoration (OMD) process enables the decoration for not only plastic products but also glasses and many other materials. These manufacture processes are commonly employed, particularly in the automotive and medical industries. In the pursuit of an eco-friendly environment, Compo-SiL®silicone-based decorative film provides a variety of decorative appearance and tactile effects, as a new highly durable material choice and a replacement for thermoplastic film.

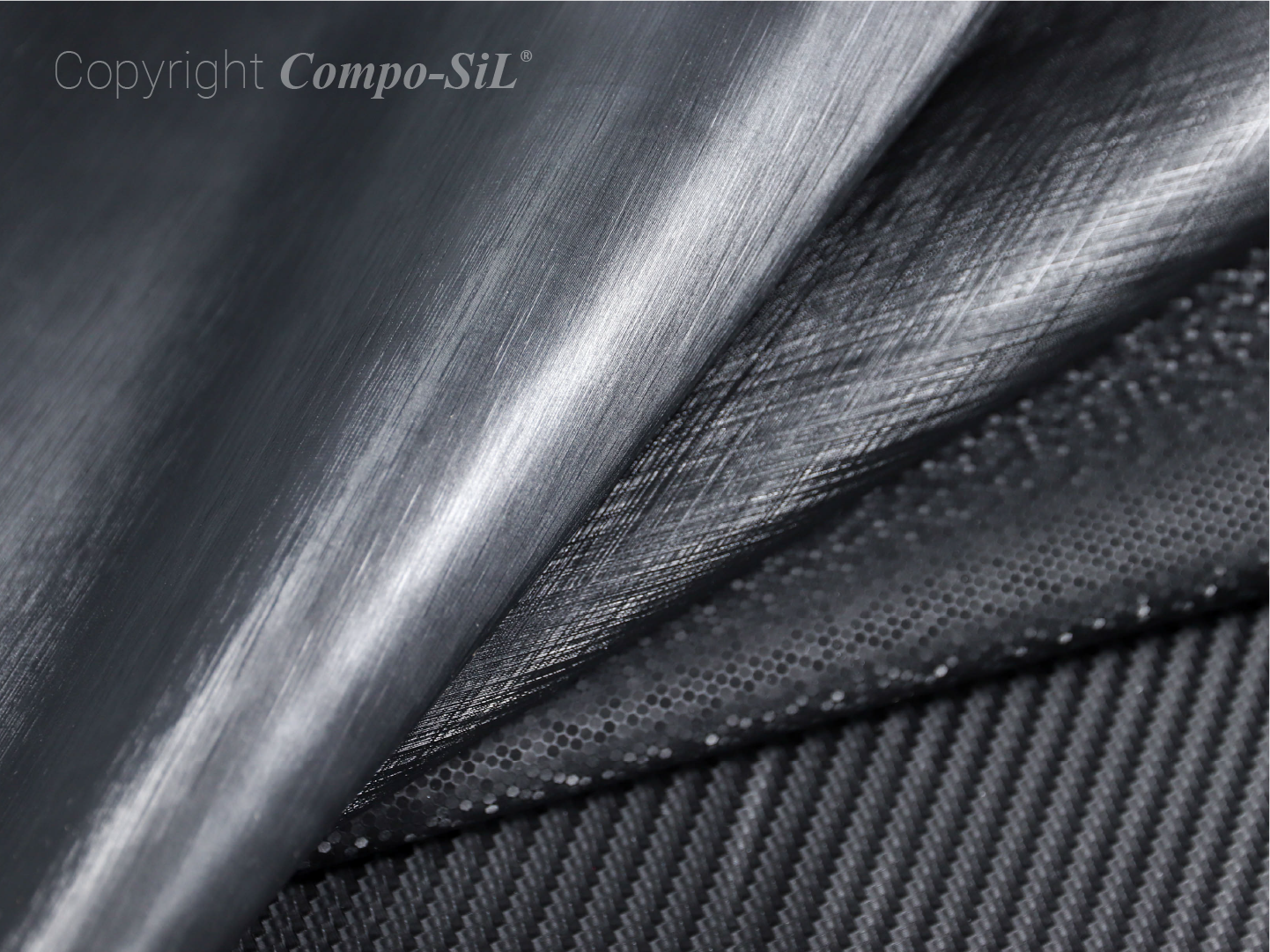

Compo-SiL® Versatility in IMD and OMD

Compo-SiL® IMD/OMD Industrial Applications

IMD and OMD process are widely used in almost every industry. Here are some examples for the applications:

- Automotive industry: Interior trim, door trim, door panel, dashboard components, center consoles, ceiling, touch screen panel, instrument panel, decoration panel, lighting components, human machine interface, etc.

- Medical industry: EEG, ECG equipment, medical equipment, laboratory equipment, diagnostic equipment, imaging devices, medical furniture, control panels, hospital bed controls, patient monitoring devices, health monitoring wearable, etc.

- Consumer product: Phone case, mouse, AR/VR glasses, phone, TV, laptop, home appliances panel, etc.

Compo-SiL® Performance Benefits

Eco-friendly

Compo-SiL®silicone-based decorative film stands as an eco-friendly alternative to thermoplastic films, PU, and various other plastic films. Our materials exhibit halogen-free and low VOCs properties, aligning with IATF 16949, ISO 14001, RoHS, and REACH standards. This commitment to environmental responsibility ensures a sustainable and healthy manufacturing ecosystem.

Weather and Hydrolysis Resistance

Our silicone-based materials showcase exceptional resistance to hydrolysis and weathering, ensuring the effective functionality of our materials in high-humidity environments and guaranteeing prolonged product lifespan.

Chemical Resistance, Biocompatible, Sterilizable and Easy to Clean

Transparency Excellence for IMD/OMD Parts

Revolutionizing Bonding: Silicone Decorative Films in IMD/OMD

With Compo-SiL®technology, we’ve successfully addressed silicone adhesion and bonding challenges, enabling the laminable use of silicone-based decorative films in IMD/OMD processes. These films can bond to various surfaces, facilitating ease of integration.

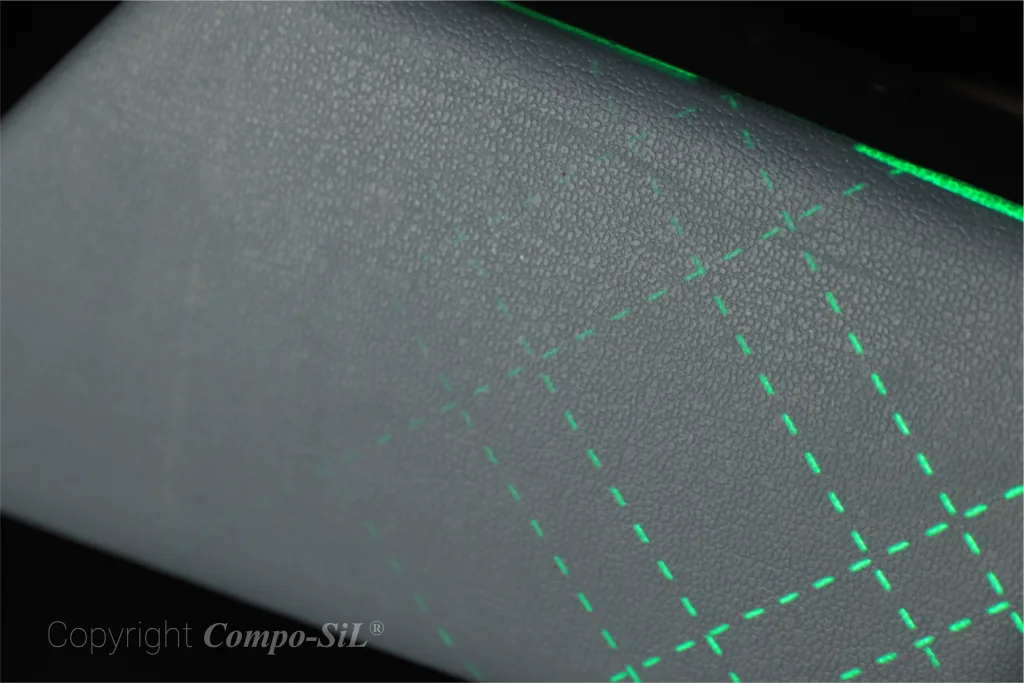

Diverse Surfaces with Additional Functions, Customization

Want to learn how we could help?

Discover More

Compo-SiL® Applications