Choosing the Right Silicone for Sports and Rehabilitation Goods

Kinesiology or elastic tape is a tape that is applied strategically to either try and enhance sporting performance or for injuries to help improve recovery times and reduce pain.1,2 The tape helps by providing support in the local area and reducing inflammation by affecting circulation. 3

The tape was popularized during the 2008 Olympics, where many athletes wore it. Since then, kinesiology tape has become a preferred treatment option for many physical therapists. Its elastic nature, designed to mimic the skin’s natural elasticity, makes it comfortable to wear and does not restrict movement.

However, kinesiology tape is not the only sports product that benefits from elasticity. Taped sports clothing incorporates integrated structures that mimic kinesiology tape, combining some of its benefits within clothing. This integration offers the advantages of compression without restricting movement.4

Silicone Materials

Silicone is an ideal material for integration into products that require flexibility and elasticity. Silicone is UV-resistant, moisture- and chemical-resistant, waterproof, heat-resistant, anti-slip, skin-friendly, and offers excellent high tensile strength, making it highly flexible.

The impact absorption properties of silicone and the fact that it is lightweight and easy to integrate into textile manufacturing have meant silicone is now being used for sports clothing in a series of fields as a way of preventing athlete injuries.5 Compression gear is also thought to improve recovery rates and help with injury rehabilitation.

Sports or compression goods require a high degree of elasticity to avoid hindering athletes’ movements as well as to prevent tearing or damage to the garment. Silicone can provide this flexibility. Hydrolysis resistance is another added bonus as this helps the material withstand repeated washes so the goods do not degrade after frequent washing.

Most current kinesiology tapes are made from cotton and nylon. The nylon provides elasticity in the material, and the cotton helps with the breathability of the material. However, when it comes to biomedical applications, silicone derivatives have a long history of use due to their excellent biocompatibility. This biocompatibility means that they can be used both in devices that will be implanted and those that will come into contact with the skin.

However, while silicone possesses numerous desirable properties for creating elasticated or compressive clothing, medical products, or protective gear and goods, it also presents certain challenges in handling and processing. One particular challenge arises when trying to incorporate silicone into clothing products. Due to its low surface energy, bonding silicone with other materials can be rather difficult, making it hard to manufacture silicone into clothing items.6

While the weak intermolecular interactions that contribute to silicone’s chemical inertness and water resistance are advantageous, they also pose a challenge when attempting to create the bonds required for adhering silicone to another surface.

Compo-SiL®, a recent development, surpasses the limitations of prior silicone manufacturing techniques, enabling you to fully leverage the outstanding properties of silicone in your products.

Compo-SiL®

The innovative Compo-SiL® bonding technology addresses these challenges by incorporating an ultra-thin layer above the silicone. This layer enhances surface energy and improves wettability properties. The quality of the adhesion process has been robustly tested using a combination of standards as well as in-house testing protocols.

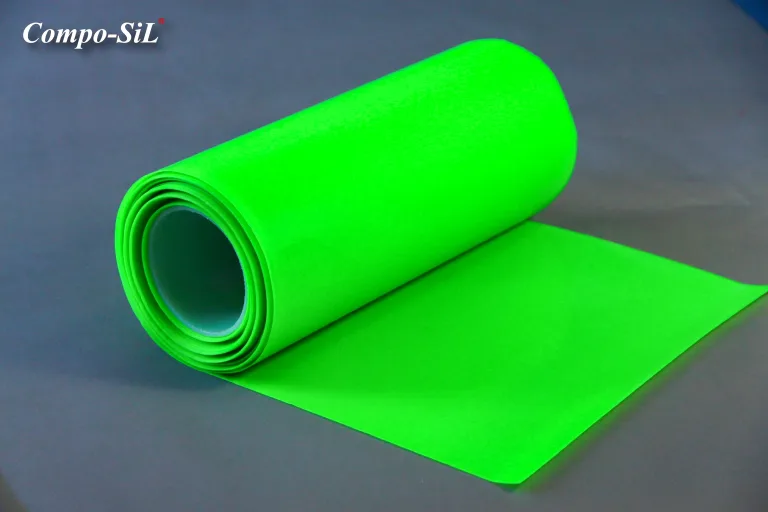

The Compo-SiL® materials series can now be printed on roll-to-roll sheets of various sizes to incorporate all the benefits of silicone into your garments. Owing to General Silicone’s extensive expertise in silicone processing and manufacture, there are also options for customizing the exact properties of the silicone to perfectly match your application.

The impact absorption properties of silicone and the fact that it is lightweight and easy to integrate into textile manufacturing have meant silicone is now being used for sports clothing in a series of fields as a way of preventing athlete injuries.5 Compression gear is also thought to improve recovery rates and help with injury rehabilitation.

Sports or compression goods require a high degree of elasticity to avoid hindering athletes’ movements as well as to prevent tearing or damage to the garment. Silicone can provide this flexibility. Hydrolysis resistance is another added bonus as this helps the material withstand repeated washes so the goods do not degrade after frequent washing.

Most current kinesiology tapes are made from cotton and nylon. The nylon provides elasticity in the material, and the cotton helps with the breathability of the material. However, when it comes to biomedical applications, silicone derivatives have a long history of use due to their excellent biocompatibility. This biocompatibility means that they can be used both in devices that will be implanted and those that will come into contact with the skin.

However, while silicone possesses numerous desirable properties for creating elasticated or compressive clothing, medical products, or protective gear and goods, it also presents certain challenges in handling and processing. One particular challenge arises when trying to incorporate silicone into clothing products. Due to its low surface energy, bonding silicone with other materials can be rather difficult, making it hard to manufacture silicone into clothing items.6

While the weak intermolecular interactions that contribute to silicone’s chemical inertness and water resistance are advantageous, they also pose a challenge when attempting to create the bonds required for adhering silicone to another surface.

Compo-SiL® Materials

The Compo-SiL® elastic film (SR series) is a highly resilient and stretchable material that can be readily used in a number of product applications, including for sports tape and apparel. The secret to the outstanding performance of the Compo-SiL® product range is the unique bonding technology, which allows the Compo-SiL® materials to take advantage of the material properties of silicone.

Compo-SiL® utilizes HMA/PUR to integrate silicone, and the resulting material can subsequently be applied in protective gear, compression goods, and various other garments. The final result is a water-resistant, highly durable material that will not degrade after multiple washes or frequent use. Silicone is skin-friendly, making Compo-SiL® an excellent choice for clothing.

Customization of the material is also possible, such as upgrades to make Compo-SiL microbial resistant and compliant with ISO 22196:2011, JIS Z 2801: 2012, and ISO 21702:2019 standards as well as ASTM G21 for the antifungal activity.

Many of the odors commonly associated with sports gear are a result of microbial colonies forming. Therefore, this option is not only excellent for potential medical applications or situations involving wounds but also for producing garments that remain odor-free.

The SR series offers a maximum width of 1400 mm, providing you with greater flexibility in your designs.

General Silicones

If you are manufacturing compression leggings, high-performance sportswear or apparel for high-impact sports, contact General Silicones to find out how their Compo-SiL® technology could improve your product offering.

Compo-SiL® is also suitable for use in joint supports and support bars, which could enhance the durability and quality of your garments and lead to improved customer satisfaction.

References and Further Reading

- Williams, S. et al. (2012) ‘Kinesio Taping in Treatment and Prevention of Sports Injuries’, Sports Medicine, 42(2), pp. 153–164. Available at: https://pubmed.ncbi.nlm.nih.gov/22124445/.

- Reneker, J.C. et al. (2018) ‘Effectiveness of kinesiology tape on sports performance abilities in athletes: A systematic review’, Physical Therapy in Sport, 31, pp. 83–98. Available at: https://www.sciencedirect.com/science/article/abs/pii/S1466853X16301857?via%3Dihub.

- Craighead, D.H., Shank, S.W., Volz, K.M., and Alexander, L.M. (2017) ‘Kinesiology tape modestly increases skin blood flow regardless of tape application technique.’ Journal of Performance and Health Research, 1, 1-17. [Online] Available at: https://www.scilit.net/article/e1fb961c060ad0d85a412149b7b4488f

- Kit Radar (2023) Does kinesiology taped clothing really work?, Kit Radar. Available at: https://kitradar.com/blogs/startups/does-kinesiology-taped-clothing-really-work (Accessed: 19 September 2023).

- Hughes, A., Driscoll, H. and Carré, M. (2020) ‘Development of Silicone Elastomer for Use in the Assessment of Padded Clothing in Rugby Union’, The 13th Conference of the International Sports Engineering Association. Available at: https://www.mdpi.com/2504-3900/49/1/77.

- What Does Surface Energy Mean and Why Is It Important? (2018) BDK. Available at: https://www.bdk.uk.com/2018/08/surface-energy-why-important-adhesive-selection/ (Accessed: 19 September 2023).