Membrane Keypad Explained: How They Work & Their Uses

1. What is a Membrane Keypad? How Does a Membrane Keypad Work?

A membrane keypad is a type of keyboard or input device that uses a flexible membrane layer with conductive traces to register keystrokes. When a key is pressed, the top membrane layer flexes and pushes down on the holes layer, making contact with the conductive traces on the bottom layer.

This action completes the circuit and sends the corresponding signal to the device, which processes the input almost instantly. The simplicity and affordability of this technology make it ideal for industrial applications requiring minimal input.

Membrane keypads are named for the thin, flexible membrane used in their construction. They are known for being affordable, quieter, and more resistant to liquids and dust than mechanical keyboards, making them suitable for various environments and applications.

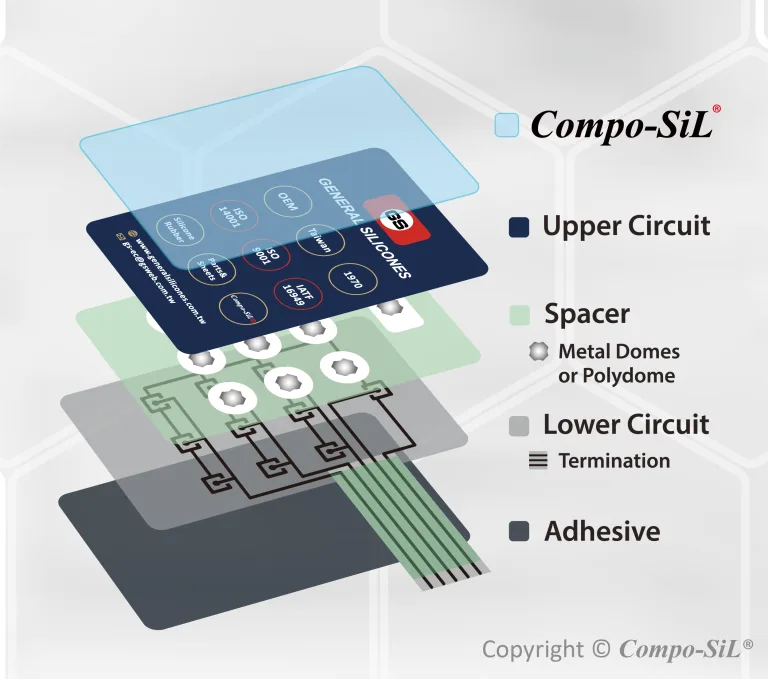

Construction of a Membrane Keypad: Components

Constructing a membrane switch keypad involves layering several components to create a functional and user-friendly interface. These layers work together to create a robust, efficient, and customizable input solution suitable for a wide range of applications. Here is a detailed breakdown of its key layers and components:

- Graphic Overlay: This top layer displays the interface for users, providing visual cues and protection against wear. It’s typically made from printed polyester or polycarbonate. Also, silicone is also another new material for making graphic overlay for membrane keypads.

- Top Spacer: Located beneath the graphic overlay, this layer bonds the overlay to the dome retainer. It ensures the layers remain securely in place while allowing flexibility for key presses.

- Dome Retainer: This layer holds metal or polyester domes, which provide tactile feedback when pressed.

- Spacer: Situated below the dome retainer, this spacer layer separates the top and bottom circuits. It includes ventilation cuts to allow air movement, preventing the circuits from closing until a key is pressed.

- Circuit Layer: Printed with conductive inks like silver or carbon on a flexible polyester film, this layer completes the circuit when the keypad is activated.

- Mounting Adhesive: The bottom layer, which attaches the entire keypad assembly to the device. This layer ensures the keypad remains firmly attached, even under frequent use.

Advantages of Membrane Keypad

Membrane keypads are a popular choice across various industries, due to their unique combination of benefits. Here are some key advantages that make them indispensable in modern technology:

Versatile Customization: Membrane keypads can be tailored to specific needs with different key shapes, sizes, colors, and graphics. This flexibility allows for the creation of versatile product designs that match the exact requirements of any device or environment.

Extended Lifespan: The sealed construction of membrane keypads protects internal components from moisture, dust, and other contaminants, ensuring a long operational life for products.

User-Friendliness: Designed to provide a seamless and intuitive end-user experience and operability, membrane keypads offer clear, responsive feedback. This makes them ideal for applications requiring frequent or extended use.

Perfect for Hygiene-Sensitive Settings: The easy-to-clean, sealed surfaces of membrane keypads prevent the buildup of dirt and bacteria, making them perfect for medical devices and food processing equipment

Low-Profile and Lightweight: With their sleek, modern appearance, membrane keypads enhance the aesthetic of any device. They are exceptionally thin and lightweight, making them perfect for applications that demand minimal space and weight.

2. Common Applications of Membrane Keypads

Membrane keypads are widely used in various fields due to their versatility, durability, and ease of customization. Here are some common applications:

Consumer Electronics

Membrane keypads are integral to many consumer electronics, such as remote controls, calculators, and household appliances. Their lightweight, durability, and ability to be customized with different graphics and layouts make them ideal for these devices. They offer a sleek, user-friendly interface that can be designed to fit compact spaces and withstand frequent use.

Medical Devices

In the medical field, membrane keypads are used in devices like patient monitors, infusion pumps, and diagnostic equipment. Combined with the material like silicone, their sealed design can make them easy to clean and resistant to contaminants, which is crucial in maintaining hygiene and preventing infections.

Industrial Equipment

Membrane keypads are also common in industrial settings, where they are used in control panels and machinery. Its feature of robust construction provides reliable and responsive input, essential for operating heavy machinery and industrial processes efficiently.

3. Features of Graphic Overlay for Membrane Keypad

A graphic overlay is the outermost layer of a membrane keypad, serving as the interface between the user and the device. These overlays are printed with symbols, text, and graphics to guide the user. They are typically made from durable materials such as polyester (PET) or polycarbonate (PC), or even innovative options, such as silicone.

Key features of graphic overlay include:

- Flexibility: They can conform to various shapes and sizes of devices, accommodating different requirements for membrane keypad designs.

- Visual Appeal: These overlays can incorporate vibrant colors, high-resolution graphics, and precise printing techniques to enhance aesthetic appeal.

- Tactile Feedback: They can integrate embossed or raised features to provide tactile feedback, enhancing the user experience.

A wide range of custom graphic overlay options is available to meet diverse design requirements. These options include backing plates with various materials and finishes, an extensive palette of colors achievable through Pantone references or sample matching, and multiple embossing styles such as Braille, bubble, logo, and rim embossing.

Graphic overlays are essential for providing a visually appealing finish and functional user interface, impacting both the usability and aesthetic design of the device.

Experience Advanced Material Technology for Graphic Overlay with Compo-SiL®

A typical membrane keypad overlay material is PC or PET. However, with our technology, a silicone-based layer can be bonded to these materials, significantly enhancing their properties. This makes silicone-based layers a premium choice for producing higher-quality graphic overlays.

Silicone’s inherent chemical resistance allows for cleaning with solvents or alcohol while maintaining hygiene standards. Compared to PC and PET, silicone performs much better in this regard. With long-term use, cleaning agents can damage PC and PET surfaces. However, silicone can withstand repeated cleaning with alcohol and detergents without any issues. This makes silicone a more suitable overlay material for medical membrane keypads.

Also, other materials face hydrolysis issues, meaning that with long-term use or cleaning, their surfaces can hydrolyze and become sticky. However, silicone does not have this problem due to its outstanding hydrolysis resistance.

Finally, additives like antibacterial agents can be integrated into the silicone layer, inhibiting bacterial growth and reducing surface contamination.

These features not only extend the product’s lifespan but also ensure a cleaner, safer user interface for membrane keypads. This makes Compo-SiL® ideal for various demanding applications and harsh environments, including exposure to moisture, water, dust, and chemicals. It’s perfect for home appliances, medical devices, electronics, and industrial controls.

4. Experience Superior Smart Surface Solutions for Membrane Keypads with Compo-SiL®

Compo-SiL® is at the forefront of membrane keypad graphic overlay innovation with our advanced silicone material technology. Our transparent films built for graphic overlay offer unmatched durability, bacterial resistance, hydrolysis resistance, and ease of cleaning. These overlays can include antibacterial additives to enhance hygiene, making them perfect for demanding applications. This ensures reliable performance even in harsh environments, providing membrane keypad users with a high-quality, long-lasting Smart Surface solution.

Partnering with our parent company, General Silicones, which boasts over 50 years of experience in producing custom membrane keypads, we offer a complete solution for custom membrane switches. Together, we blend superior graphic overlay technology with General Silicones’ manufacturing expertise to set new standards in quality and performance for membrane keypads. Experience the difference in quality and innovation—contact us today to join this revolution!