New Film for Antimicrobial Surface Protection in Healthcare

Preventing the Spread of Viruses, Fungi, and Bacteria Through Surfaces at Hospitals and Healthcare Facilities

Hsinchu, Taiwan, September 9, 2021 – General Silicones (GS), an expert manufacturer of silicone products, shares how its silicone rubber film with antiviral and antibacterial properties is a simple solution for adding protection to exposed surfaces. As a supplier of medical grade silicone parts with over 50 years in experience, GS took on the challenge to support the healthcare industry with new means to easily add protection against viruses, bacteria, and fungi on high touch surfaces.

The ongoing COVID-19 crisis has shown how viruses and bacteria must be prevented from spreading through healthcare facilities as early as possible. Surfaces with active ingredients are a tool of growing importance to help suppress the spread of increasingly resistant and dangerous microbes, as even the most frequent cleaning regimen cannot prevent contamination. Hospitals and healthcare facilities can now apply protective antimicrobial silicone rubber film from General Silicones to high-touch surfaces frequently used by patients and visitors.

Patented Technology for Strong Silicone Rubber Adhesion

The antimicrobial film ships in rolls that can be easily cut and adjusted in size. Thanks to the patented technology of GS, contractors can firmly apply the silicone rubber material with standard adhesives to high-touch surfaces in hospitals, such as bed rails and frames, moveable lamps, tray-and bedside tables, handles, IV poles.

High-touch objects throughout the facilities such as elevator buttons, door and staircase handle, registrations desks, chairs, and furniture in waiting rooms, cafeterias, and restaurants can reduce the risks by applying the film.

Firm Anti-Slip Grip for the Weak and Elderly

Weak hospital patients need a firm grip to support their bodies during recovery. Silicone rubber is an excellent material for creating surfaces with anti-slip properties. For example, various sport and textile products use silicone to prevent slipping. GS makes antimicrobial films with custom anti-slip properties on customer demand, allowing healthcare facilities to provide additional security and support to surfaces.

An Eco and Skin Friendly Material

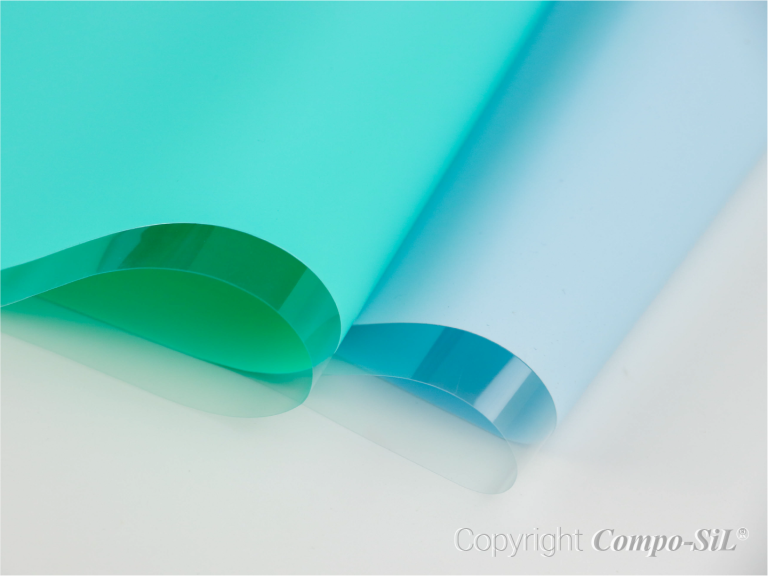

Silicone rubber is well-studied material in the medical industry. Medical grade silicone is used for devices during sensitive procedures, and baby products use silicone for its antiallergic properties. These properties make silicone an excellent alternative to plastics. The qualities of silicone rubber make it a unique and sustainable alternative to plastic as well. The Compo-SiL® silicone rubber film surface is made of 100% silicone. This material is biocompatible and bio durable, non-toxic, antibacterial, and chemically resistant. It allows chemical cleaning with alcohol without affecting the surface material. The material itself is derived from silicon, an element found mainly in the earth’s crust, combined with other natural elements, including oxygen and hydrogen, making it a much safer product than plastics.

Healthcare facility managers and contractors interested in more information on antimicrobial Compo-SiL® films can contact General Silicones at [email protected]

About General Silicones

General Silicones (GS) was founded in 1970 in Taipei, Taiwan, and is now represented worldwide – including Europe, China, Japan, and South-East Asian countries. GS is a major distributor of silicone materials and an active silicone products manufacturer with ISO 9001, IATF 16949, and ISO 14001 certifications. The company has manufacturing plants in Hsinchu, Taiwan; Wujiang, China; and Bac Giang, Vietnam. With decades of experience in this field, GS has the ability and capacity to provide a wide range of silicone products for many industries, including medical, automobile, consumer products, electronics, and IT. For more information about GS, please visit www.generalsilicones.com. For more information on Compo-SiL®, please visit www.compo-sil.com